Headbox is the source of paper making and the key part of paper making machine. Its structure has a decisive role in the pormation and quality of paper.

HSFD collects more than 380 European and American suppliers commonly used in the paper industry, and has established long-term partnership with 266 of them according to actual needs to jointly serve customers in the paper industry.

The wire section is the main equipment of the paper machine and consists of long wire, overlapping wire and clamping wire. The main functiong is to remove most of the moisture from the online pulp and form wet paper sheets.

HSFD collects more than 380 European and American suppliers commonly used in the paper industry, and has established long-term partnership with 266 of them according to actual needs to jointly serve customers in the paper industry.

Press section have four roll three-press, five roll rhree-press. Its function is to further dehydrate the wet paper web form the wire section through mechanical exrusion to improve the dryness of the paper sheet before it enters the drying section.

HSFD collects more than 380 European and American suppliers commonly used in the paper industry, and has established long-term partnership with 266 of them according to actual needs to jointly serve customers in the paper industry.

Drying section consists of cylinder drying, air floating drying, and impact drying. Its function is to remove the moisture by high temperature after the paper sheet is squeezed. Meanwhile, the strength and smoothness of the paper are improved.

HSFD collects more than 380 European and American suppliers commonly used in the paper industry, and has established long-term partnership with 266 of them according to actual needs to jointly serve customers in the paper industry.

The sizing and coating section consists of a glue application roll or a coating roll and a feeding beam. Its function is to apply a layer of sizing agent or coating on both side or one side of the paper to improve the performance of the paper.

HSFD collects more than 380 European and American suppliers commonly used in the paper industry, and has established long-term partnership with 266 of them according to actual needs to jointly serve customers in the paper industry.

Calender section hase soft calendering , hard calendering and super calendering. Calendering is used to trim the paper, the smoothness and glossiness of the paper sheet are improved.

HSFD collects more than 380 European and American suppliers commonly used in the paper industry, and has established long-term partnership with 266 of them according to actual needs to jointly serve customers in the paper industry.

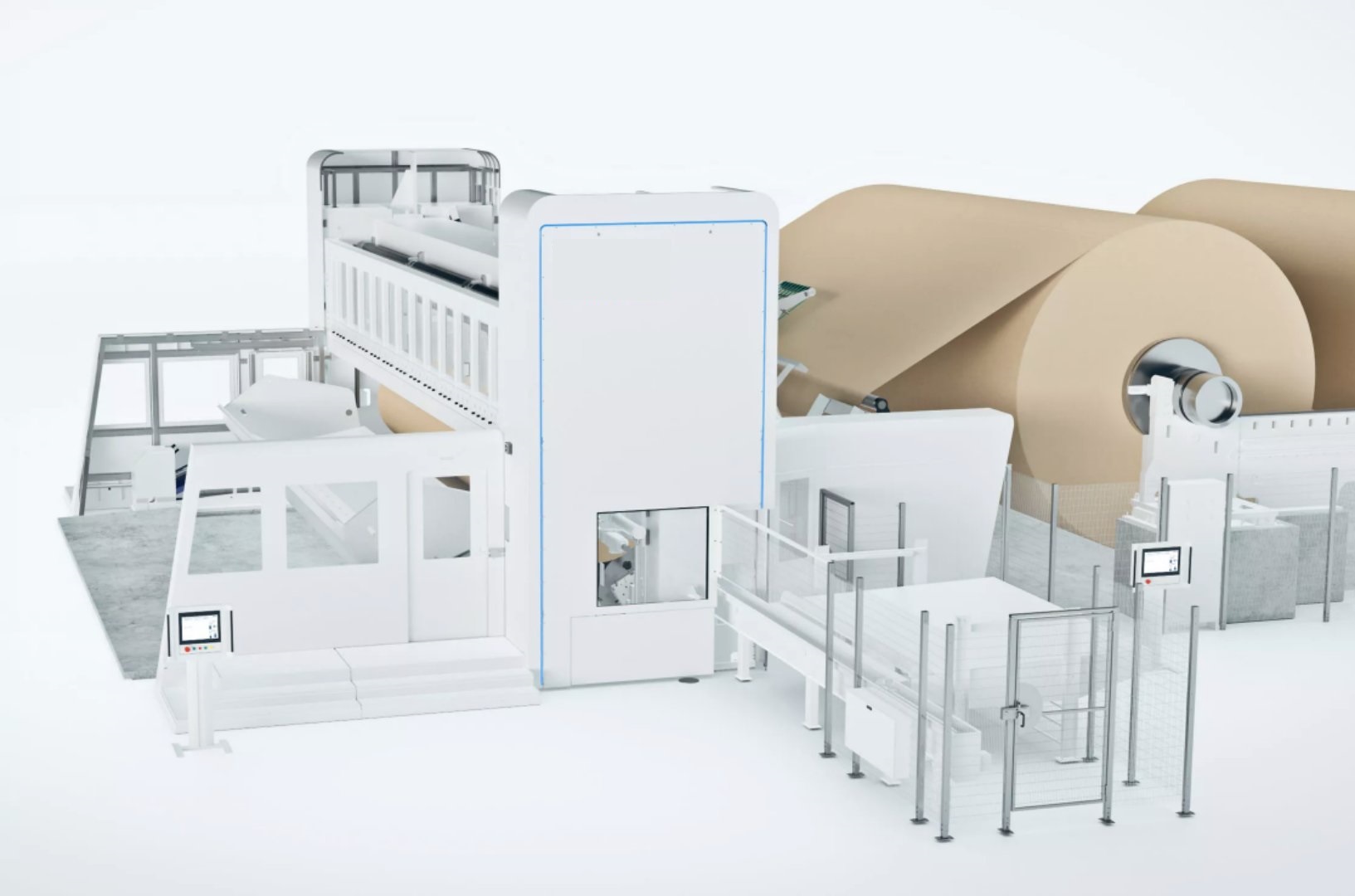

Reel section si to reel the paper to a lage roll, and ready for the next rewinding and slitting.

HSFD collects more than 380 European and American suppliers commonly used in the paper industry, and has established long-term partnership with 266 of them according to actual needs to jointly serve customers in the paper industry.

Rewinder section is the end section of the paper machine and cuts the rexwinded master roll.

HSFD collects more than 380 European and American suppliers commonly used in the paper industry, and has established long-term partnership with 266 of them according to actual needs to jointly serve customers in the paper industry.