Waste paper bag and loose paper processing, and realize feeding from collection to pulper.

Pulping machine is the main equipment used to treat pulp board, damaged paper and waste paper. The pulper mainly comprises a roating disc and blades, a trough body provided with a sieve plate and a bottom knife, and vertical and horizontal pulpers.

The Deflaker eliminates pulp lumps and scraps of paper on the premise of not damaging fibers as much as possible. The Deflaker consists of a heigh-speed rotary table and a fixed plate fixed on the casing.

Cleaner is a device that uses centrifugal principle to remove impurities with density different from that of slurry. Can be used in various slurry purification systems, mainly removing heavy impurities such as sand and gravel with density higher than that of the slurry, iron filings and light impurities such as mixed adhesive, paraffin wax, ink partcles and the like with density lower than that of the slurry. Made of stainless steel, engineering plastics and ceramic materials.

Floater use surfactant to trap ink particles of different size by bubbles and float them onto the slurry surface, thus separating ink form the slurry. Flotaer mainly consists of gas filling device, tank body and its accessory equipment.

S-Screen is a screening device for pulp, through wich most impurities are removed. The screen mainly passes through the pressure difference inside and outside the screen cylinder and when the rotor rotates, it sends out good slurry and discharges slag slurry. The screen is mainly composed of screen drum, rotor and body.

Disk Fititer can effectively reduce the water consumption of pulp and paper products, not only can recover fibers and fillers in white water, but slso can realize the recycling of white water to achieve the purpose of reducing the water consumption of pulp and paper products. The discer mainly consists of a feed tank, a tank body, a filter disc, a disc shaft, a distribution valve, a pulp stripping spraying device, a net washing spraying device, a transmision device and the like.

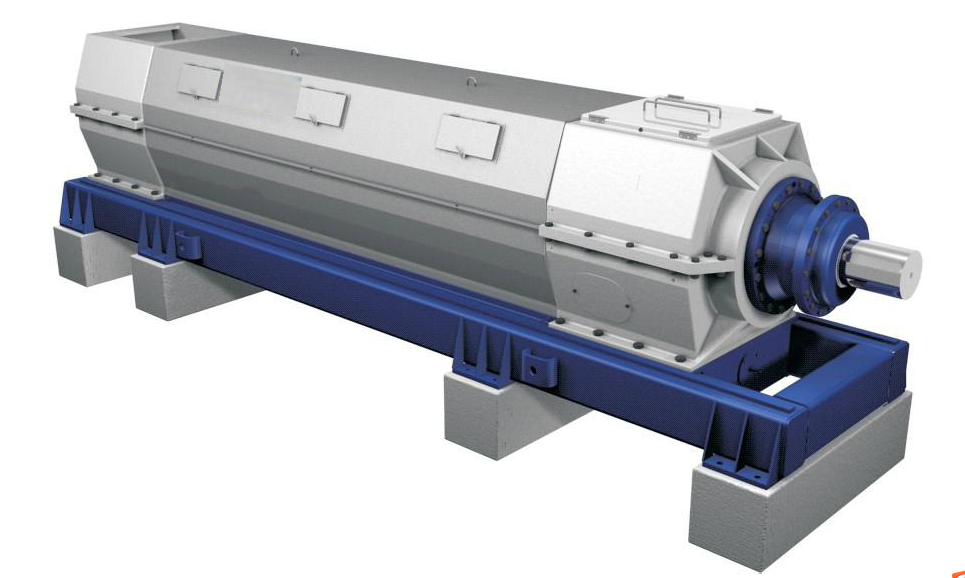

The Press Screw extruder is a device that uses mechanical pressure to compress and dehydrate slurry under high concentration and pressure to wash and extract waste liquid. It mainly consistes of a shell, a screw rod and conical plug.

Dispersion stripped ink particles, sticky substances and hot melt adhered to the fiber from the fiber and dispersed into tiny particles invisible to the naked eye. These dispersed sticky substance particles no longer appear as dust spots or spots. At the same time, after dispersion, the pulp is easier to mix with bleaching agent, thus improving the processing condition of fiber raw materials and improveing the qualtiy of the pulp. A good dispersion system can remove 99.5% of the adhesive. There are two types of dispersion: disc type and roll type.

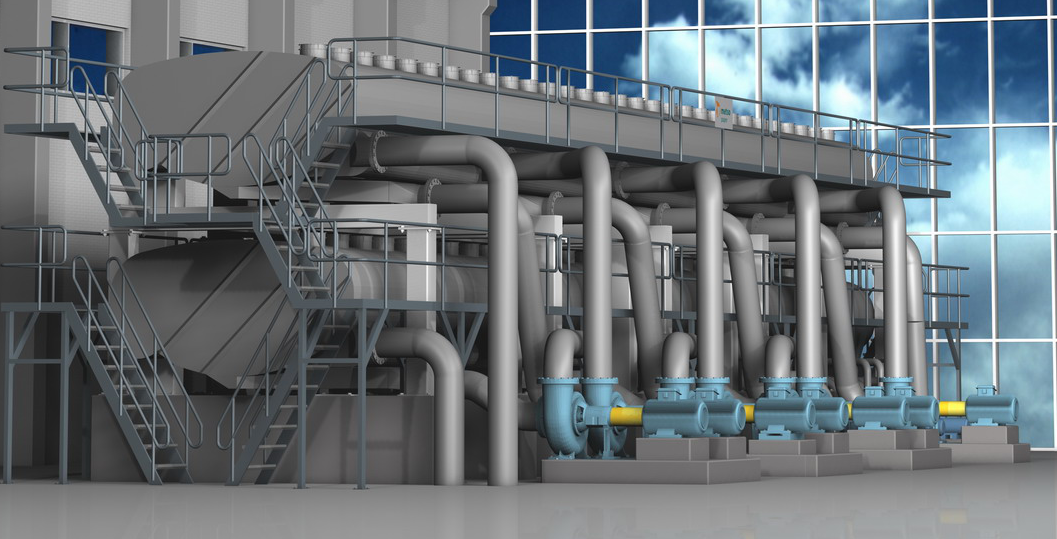

The pulp pump is mainly used for delivering pulp with concentration of less than 6%, and circularly delivering, lifting and pressurizing the pupl. Open centrifugal pump is offten used when delivering pulping.

Grinding pulp is an necessary process in paper production. Through grinding, fibers can be fluffed, cut, broomed, crushed, hydrated and mixed. The types of beaters are mainly cylindrical refiners, disc refiners and conical refiners.